Retrofitting of Diesel particulate filters for construction machines and stationary machines

The product range of TwintecBaumot Group provides economic, suitable for everyday use and future-proof solutions for original equipment and for retrofitting.

Thanks to their modular design and advanced technology, the exhaust after-treatment systems are great for retrofitting of mobile machinery and stationary equipment

- Particulate filter for construction machinery CATERPILLAR

- Particulate filter for construction machinery LIEBHERR

- Particulate filter for construction machinery KOMATSU

- Particulate filter for construction machinery TEREX

- Particulate filter for construction machinery HITACHI

- Particulate filter for construction machinery VOLVO

- Particulate filter for construction machinery ZEPPELIN

Do you want to retrofit your vehicle?

Are you interested in our retrofitting systems or are there still unresolved questions our website was not able to solve? Our service team will gladly assist you.

Request a free Quote Contact us

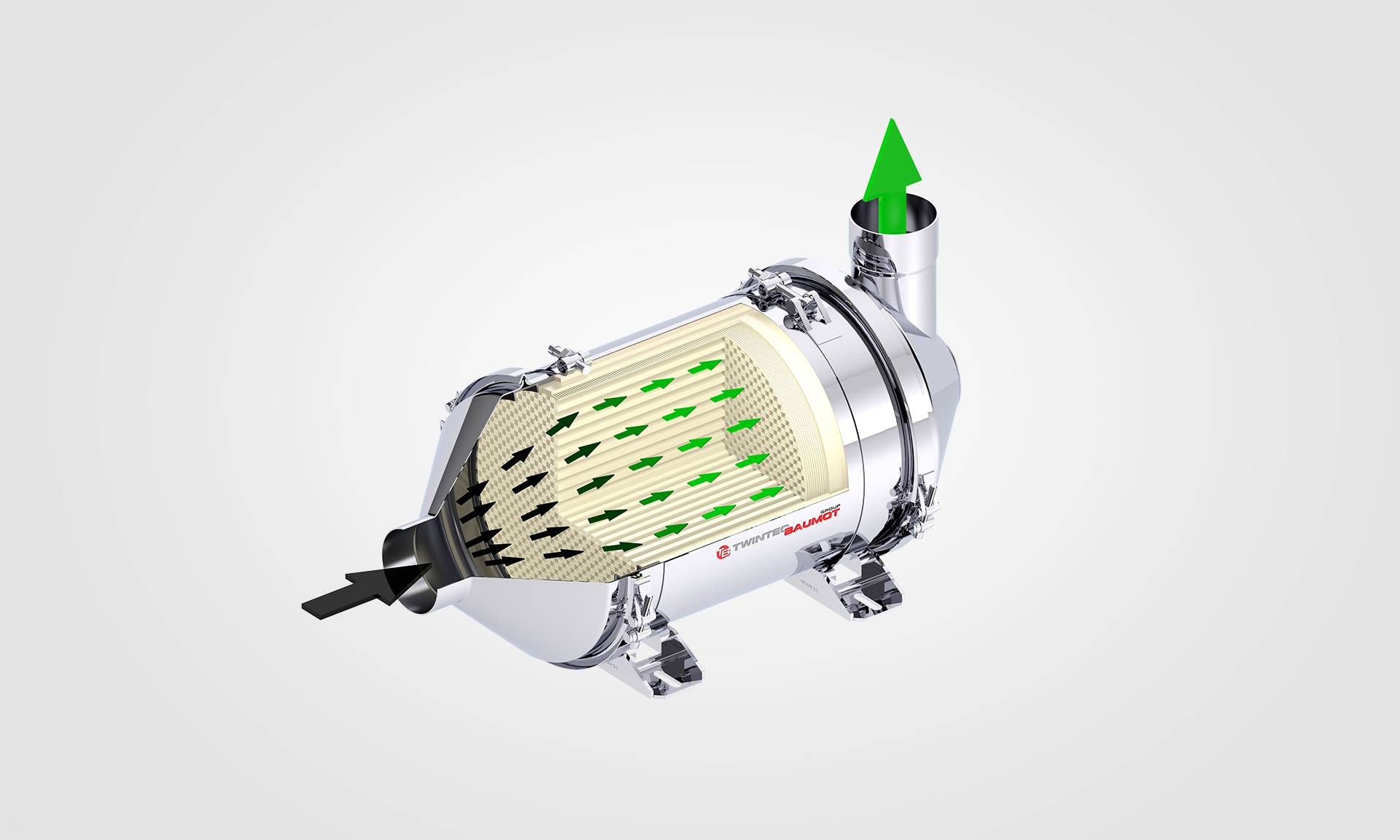

DPF-BA SYSTEM

FIELD OF APPLICATION: Passive system for low exhaust gas temperatures from 250°C

- VERT, TÜV and CARB certification, approved to EST standards in Britain, RDW in The Netherlands and DTI in Denmark

- Reduction in particulate emissions by more than 99%

- Elimination of 87% of hydrocarbons

- Reduction in carbon monoxide by more than 99%

- Low-maintenance, completely passive system with inherent regeneration capacity

- Additional or electric heating not required

- Casing made entirely of rustproof, extra-strong stainless steel capable of withstanding high temperatures

- Long lifetime thanks to the heavy-duty design of the filter

- Simple installation (replacing existing silencers)

- Permanent recording and monitoring of the filter’s functioning via data logger.

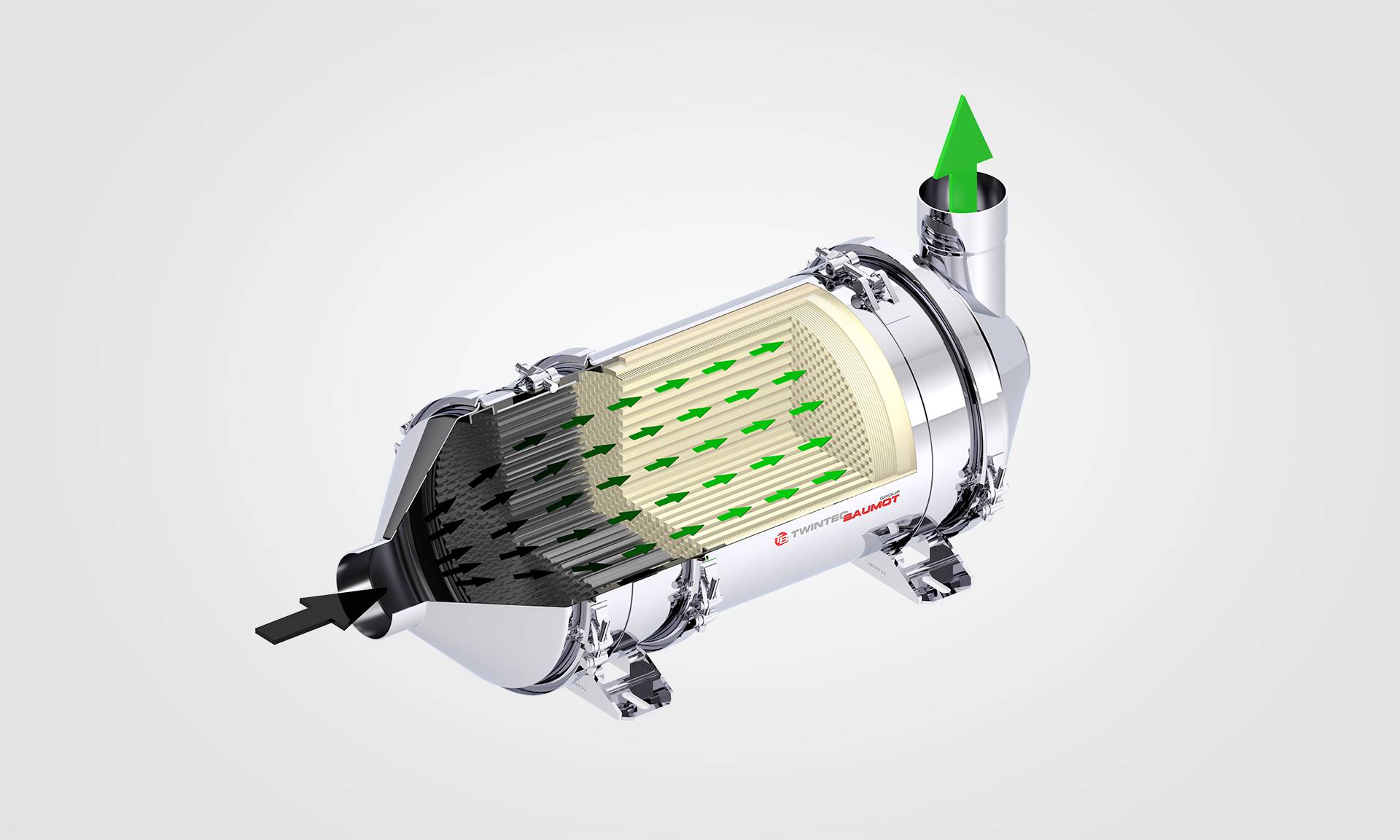

DPF-BAB SYSTEM

FIELD OF APPLICATION: Passive system for low exhaust gas temperatures from 220°C

- VERT, TÜV and CARB certification, approved to EST standards in Britain, RDW in The Netherlands and DTI in Denmark

- Reduction in particulate emissions by more than 99%

- Elimination of 87% of hydrocarbons

- Reduction in carbon monoxide by more than 99%

- Low-maintenance, completely passive system with inherent regeneration capacity

- Additional or electric heating not required

- Casing made entirely of rustproof, extra-strong stainless steel capable of withstanding high temperatures

- Long lifetime thanks to the heavy-duty design of the filter

- Simple installation (replacing existing silencers)

- Permanent recording and monitoring of the filter’s functioning via data logger.

DPF-WF SYSTEM

FIELD OF APPLICATION: Vehicles, machinery and equipment with diesel engines

- VERT certified and complies with the requirements of the TRGS 554

- Reduction in particulate emissions by more than 97%

- Effective reduction in areas PM10, PM2.5, PM1 and PM0.1

- Reduction in carbon monoxide by more than 99%

- Temperature resistant in continuous operation up to max. 350°C and temporarily to max. 400°C

- High storage capacity

- Casing made of robust material

- Special quick release system

- Easy and quick change of filter cartridges by special locking mechanism of the housing cover

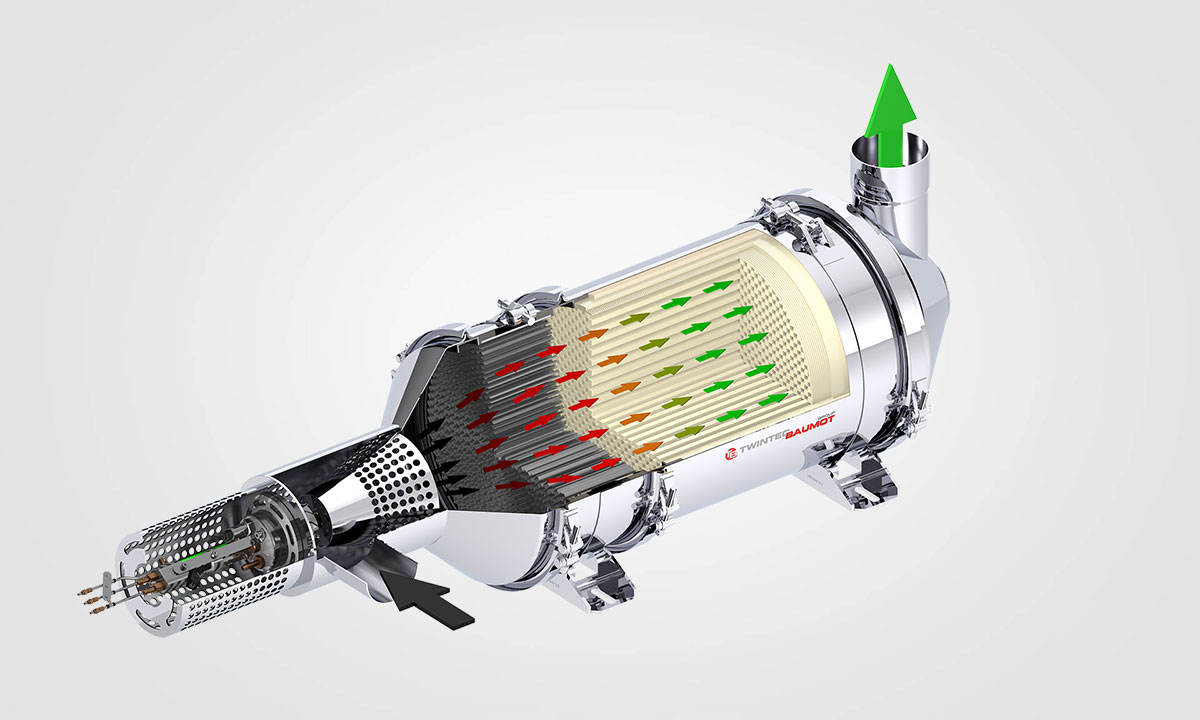

DPF-Flame SYSTEM

FIELD OF APPLICATION: Active system for low exhaust gas temperatures in internal combustion engines in the on-road sector and when using diesel fuels with high sulfur content.

- Suitable for especially low exhaust temperatures

- Permanent regeneration while in operation

- No secondary emissions

- Permanently low back-flow pressure

- Can be installed horizontally

- Independent of external energy sources

- Low fuel consumption during regeneration

- Built-in data logger for ongoing visual and acoustic monitoring of function